OUR INFRASTRUCTURE

Our works is equipped with state-of-the-art machinery with latest technology, at each stage of the manufacturing process, which in turn is the key factor in delivering quality products in least the possible time and in a cost competitive manner. Our infrastructure also enables us to provide best of the class service to our customers.

International Standards Tempering: ASTM C1048 – 04 / EN 12150

Lamination: ASTM C1172 – 03 / EN 12543 – 5

Double Glazing: ASTM C661 / EN1279 – 2

Heat Soaking: EN 1663

A brief overview of our plant and machinery :

The manufacturing facility of the company is situated Targhadia Dist. Rajkot, Gujarat, at a distance of 100 meters from NH 8B (Rajkot to Ahmedabad). The Factory lay out is spread over 1, 00,000 Sqr Ft plot of land consisting of production, warehousing, office/administration, canteen and labor colony etc. with a dedicated company owned transports.

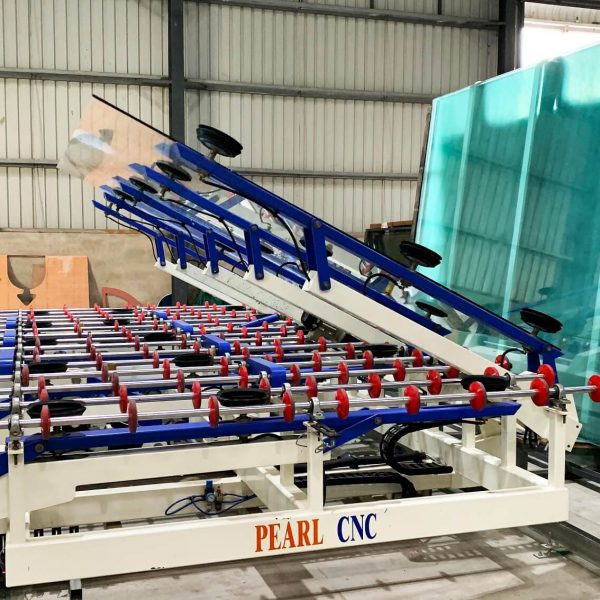

CNC Cutting Machine: To cut the glasses in exact sizes ,as per customers’ requirement.

Edge Grinding: Equipped double edger and Vertical single edging machine, in addition to cross belt grinders, to provide best possible edge finish in large volume to our ensure quality with time commitment to our customers.

Washing Machines: Enabled with hi tech washing machines, capable of washing Soft Coat glasses and thus enables us to provide glasses with best surface finish possible.

Tempering Furnace: The Biggest Tempering Furnace in Gujarat ,India. Sophisticated ‘Forced Convection Furnace’ capable of doing soft coat glasses and delivers best quality in terms of optical properties be it distortion or strength and fragmentation.

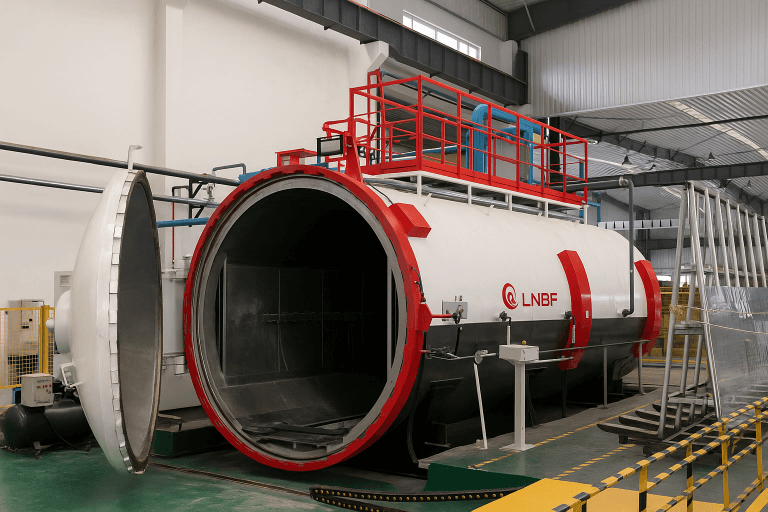

Lamination Line: Fully automatic flat lamination line including modern clean room and Autoclave to manufacture large glass sizes in best quality.

Insulated Glass Line: One of the best IGU lines in the world to manufacture all possible combinations, as per customers’ demand.