Since the tempered/toughened glass has become a safety norm for public places, shopping malls and residences the demand is high. There comes the ECHO TUFF working with industry leaders, contractors and fabricators to ensure the international standards been served always.

ECHO TUFF processes best in class Fully tempered Glass, where glass sheet is sourced from renowned glass manufactures, complying to ASTM standards. Our production environment with adequate quality and safety standards results best customer satisfaction always. Our tempering lines with the latest technology provide tempered and Heat Strengthened Glass in full compliance with t(ASTM C1048 and BS 12150 1-2). Our machines are producing best optical quality for the most delicate Low E Coatings (Single, Double, and Triple Silver) through full convection processing with temperature raising up to approx. 620°C.

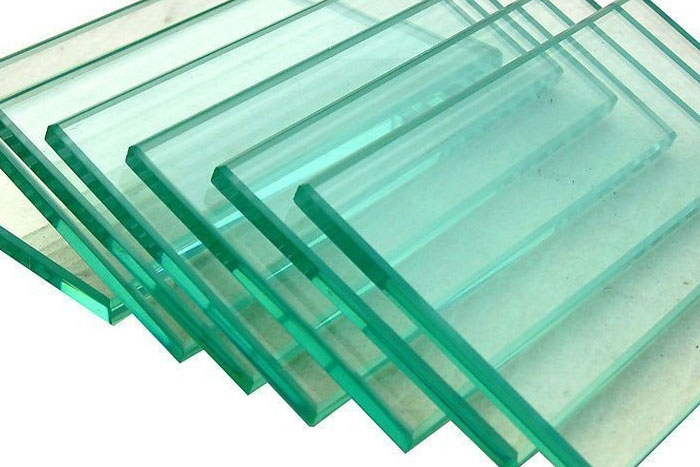

Features

- Size range : 300 X 300mm – 2440 X 5000mm

- Thickness range : 4mm – 19mm

- Types of glasses : Clear, Tinted, Reflective Soft Coat, Reflective Hard Coat, Low-E, Planistrong

Qualities

- Four to five times stronger than annealed glass of the same thickness and configuration.

- When it is broken, tempered glass fractures into small fragments that reduce the probability of serious injury as compared to annealed glass.

- Has high mechanical strength due to stresses induced during the toughening process.

- Has high thermal strength when compared with annealed glass and can withstand a temperature differential of zsrrc. It is stable in temperatures ranging from -70°C to 300°C.

- Due to high mechanical strength it can be used with mechanical fixings such as patch, spider, hinge, disc, point fixing, etc.

- Much harder to break than annealed glass and if at all broken, the breakage can be deterrent.

- Has the same solar control and UV elimination as normal annealed glass.